Consideration about a flame retarder of the application type for which a cellulose nano fiber (CNF) was used is carried in the following.

A substrate material: Polypropylene board (PP board) flash point 300-160 ℃ of the 400 ℃ and melting point

Size :200mm140mm1mm

CNF Moisture content 94.58.

The application type flame retarder was made by generating CNF2wt% aqueous solution 50g and mixing about 13 grams of bestboron.

It’s white, but when it’ll be completed, the color will be a clear application film. I have the viscosity enough for application operation.

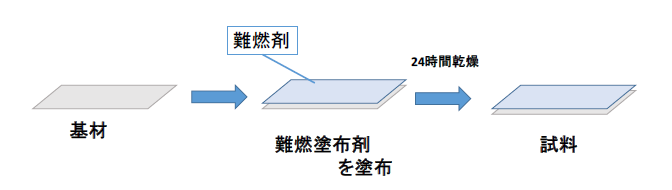

This is applied by following way.

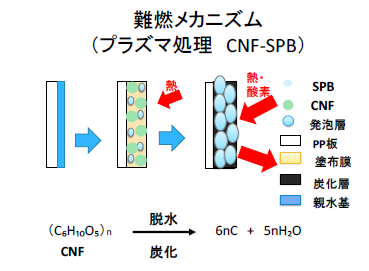

But, surface modification was performed in plasma processing because wettability of a PP board was low.

Dryness for 24 hours is performed in a dry oven after application. The temperature was set as 75 ℃.

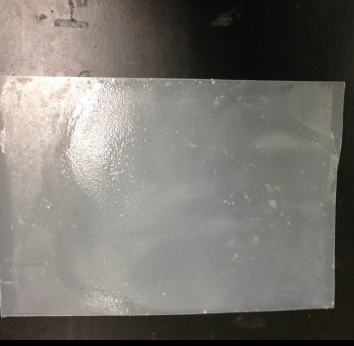

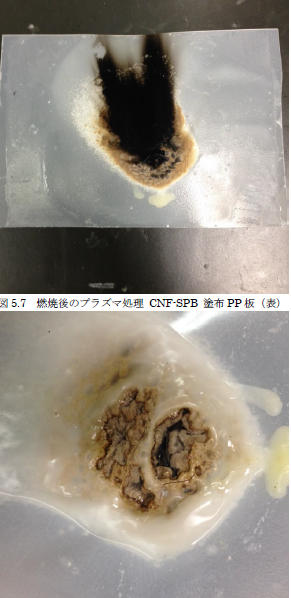

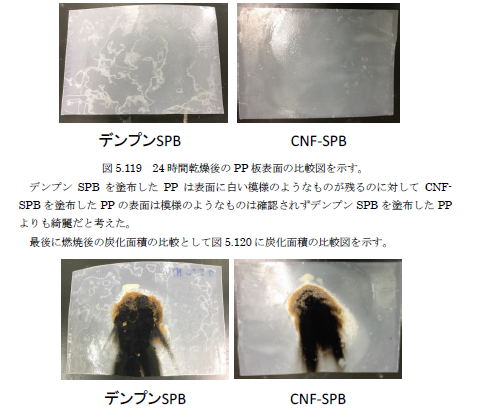

A picture of the PP board after dryness is indicated.

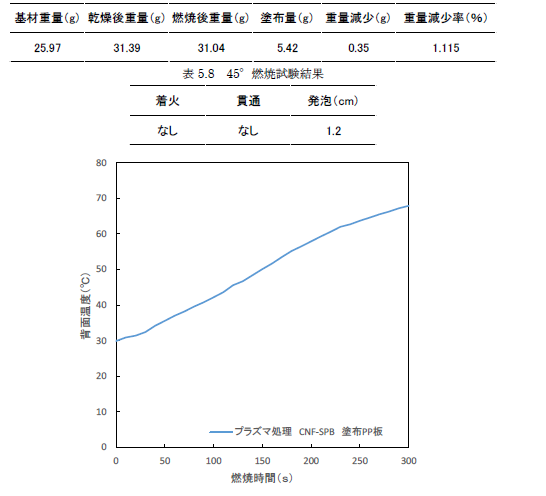

Incombustible evaluation used a combustion test way 45 ℃. It’s a combustion test way in accordance with JIS L1091, and a flame is hit and a presence of the back temperature and penetration is estimated for 5 minutes.

A testing machine used the following.

Test outcome is indicated in the following.

A fire layer was formed at the same time as a flame was cross with the surface of the PP board, and 2 layers of the char layer generated after it were that a flame was blocked off, and it was possible to endure a combustion test for 5 minutes.

Starch is being used instead of CNF by the test put into effect at the same time. This also had the similar effect, but there was difference in the appearance.

A mechanism of flame resisting is indicated in the following.